As global demand for more efficient and sustainable agriculture continues to grow, LED technology is playing a pivotal role in transforming the horticulture industry. One company at the forefront of this evolution is Cree LED, whose recent advancements highlight how a collaborative, customer-focused approach can fuel meaningful innovation.

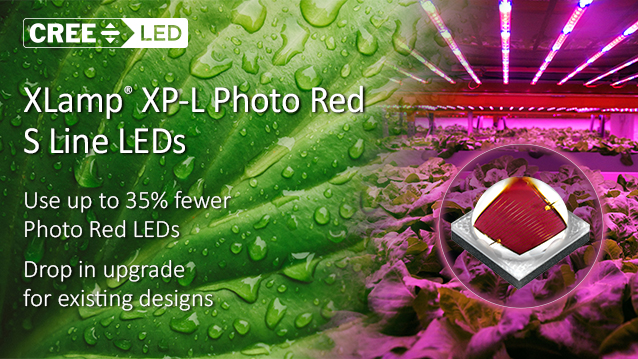

Purpose-Built for Horticulture: The XP-L Photo Red S Line

Cree LED’s latest launch, the XLamp® XP-L Photo Red S Line, is a clear example of its commitment to pushing horticultural lighting forward. This high-performance LED component is specifically engineered for plant growth applications, delivering a 660-nanometer peak wavelength – a critical band for photosynthesis – with improved efficiency in the widely adopted 3535 package footprint.

“This is the next generation of our XP-G3 S Line Photo Red LEDs,” explains Morgan Meadows Davis, Product Manager at Cree LED. “We’ve increased the light-emitting surface (LES), boosted output and enhanced efficiency, all while maintaining the footprint our customers already trust.”

One of the standout benefits of this new release is the design flexibility it offers lighting manufacturers. “Our goal is to remove common design roadblocks, so OEMs have the freedom to innovate and bring products to market faster and with greater confidence,” Davis adds.

Listening to the Market: A Collaborative Development Philosophy

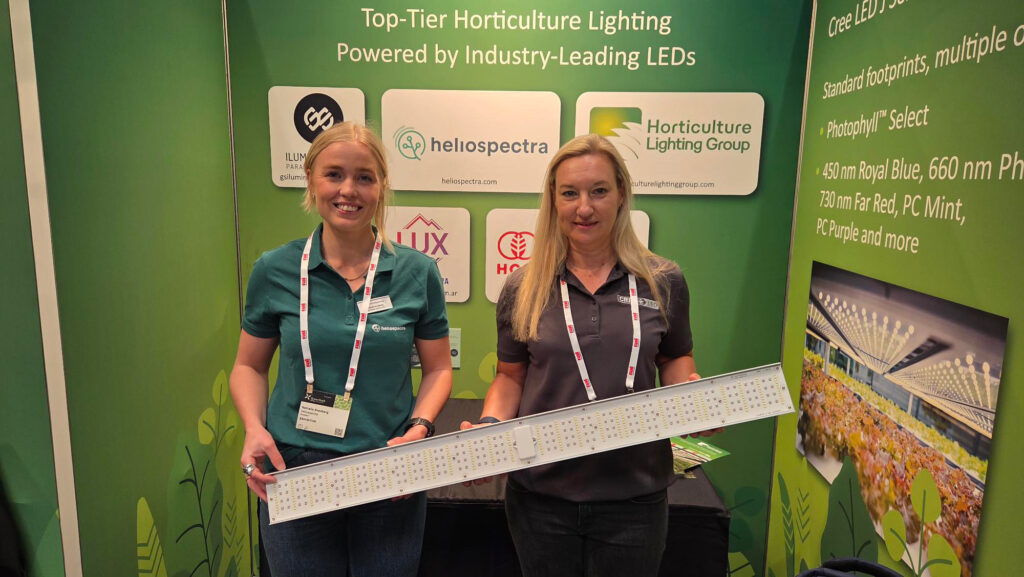

Cree LED’s approach goes beyond simply releasing new products, it’s built on deep collaboration with customers and an understanding of the challenge’s growers and lighting manufacturers face. While Cree LED doesn’t make end-use lighting fixtures itself, its focus is on delivering components that help manufacturers create better, more efficient horticultural systems.

“We provide the LEDs and the tools for simulation and design – they build the systems,” Davis explains. This collaborative approach ensures that Cree LED’s solutions are aligned with the real-world needs of the market, not just theoretical performance benchmarks.

One notable example of this feedback-driven innovation came when greenhouse growers began reporting issues with sulfur corrosion, a common challenge in horticultural environments. In response, Cree LED developed its S Line LEDs with enhanced sulfur resistance, directly addressing this need. “Listening to what’s happening on the ground helps us engineer better components,” Davis emphasizes.

Shifting Focus: From Industrial Lighting to Agricultural Solutions

While Cree LED has long been recognized as a leader in industrial and general lighting components, the company has made significant strides in expanding its horticultural portfolio. “We’ve gone from having just a couple of products suitable for horticulture to offering a full suite of high-power and mid-power solutions,” Davis says. This shift has been deliberate, reflecting Cree LED’s commitment to supporting the agriculture sector with more targeted, efficient options.

This renewed focus accelerated following Cree LED’s 2021 acquisition by Smart Global Holdings (now Penguin Solutions). Operating under a fab-light model, where components are designed in-house but manufactured through global partnerships, has allowed Cree LED to zero in on high-growth sectors like horticulture more effectively.

Addressing the Unique Needs of Plants

One of the most important distinctions in Cree LED’s horticultural strategy is recognizing that plants don’t see light the way people do. While traditional lighting metrics like CCT (Correlated Color Temperature) and CRI (Color Rendering Index) cater to human vision, these measurements are largely irrelevant to plant health and productivity.

Instead, Cree LED became the first LED supplier to fully characterize its products using horticulture-specific metrics such as Photosynthetic Photon Flux (PPF) and Red PPF %. These measures reflect how plants absorb and utilize light, making it easier for manufacturers to design lighting systems that optimize growth and yield.

Additionally, Cree LED has extended its design tools to support color mixing and spectrum simulation, enabling customers to estimate performance outcomes in horticultural metrics before ever building a prototype. This speeds up the development cycle and reduces risk for lighting manufacturers.

How LEDs Are Improving Agricultural Yields

LED technology has fundamentally reshaped how growers think about lighting. Compared to older solutions like high-pressure sodium (HPS) lamps, LEDs provide significantly higher efficiency, meaning more usable light energy reaches the plants for the same power input. This directly translates into higher yields.

Furthermore, LEDs offer greater spectral flexibility, allowing growers to tailor light wavelengths to specific crops and growth stages. Different combinations of colors can be applied throughout a plant’s lifecycle, supporting everything from germination to flowering. The precision and control provided by LEDs simply isn’t possible with traditional lighting.

LEDs have also enabled new lighting form factors, such as vertical farming solutions and intra-canopy illumination. Because they produce less radiant heat, LEDs can be placed closer to plants without causing damage, opening up new possibilities for space-efficient agricultural designs.

Looking Ahead: The Future of Horticultural LEDs

The pace of innovation in horticultural lighting shows no signs of slowing. Davis predicts ongoing advancements in Photon Efficacy (PPE) – the efficiency of converting electrical energy into photosynthetically active light. Today’s horticultural LEDs operate in the 50-80% efficiency range, leaving room for further gains.

Another frontier is customized LED optics. While current light-shaping is often done through secondary optics made from plastics or glass, these materials introduce inefficiencies. If LED components themselves can incorporate tailored light-emission patterns, manufacturers could reduce costs, improve performance and simplify fixture design.

Cree LED is already exploring these avenues, seeking ways to deliver components that drive both innovation and practicality for its customers. “We’re building LEDs that solve real problems, allowing our customers to focus on their end products without the burden of IP concerns,” Davis notes.

A Collaborative Future for Horticulture Lighting

As Cree LED approaches its 40th anniversary in 2027, its commitment to collaboration, innovation and customer-centric design remains steadfast. The horticultural market may be evolving rapidly, but Cree LED’s focus is clear: deliver components that enable lighting manufacturers to bring smarter, more efficient solutions to growers worldwide.

In an industry where light isn’t just illumination – it’s a critical input for food and sustainability – Cree LED’s approach offers a blueprint for how technology and collaboration can drive real-world impact.

Additional Resources

Horticulture Applications

Horticulture LEDs Product Guide

XLamp® Horizon LED LEDs

XLamp® Horizon LED Design Guide

Photophyll™ Select LEDs

Photophyll™ Select Reference Design

XLamp® XP-L Photo Red S Line LEDs